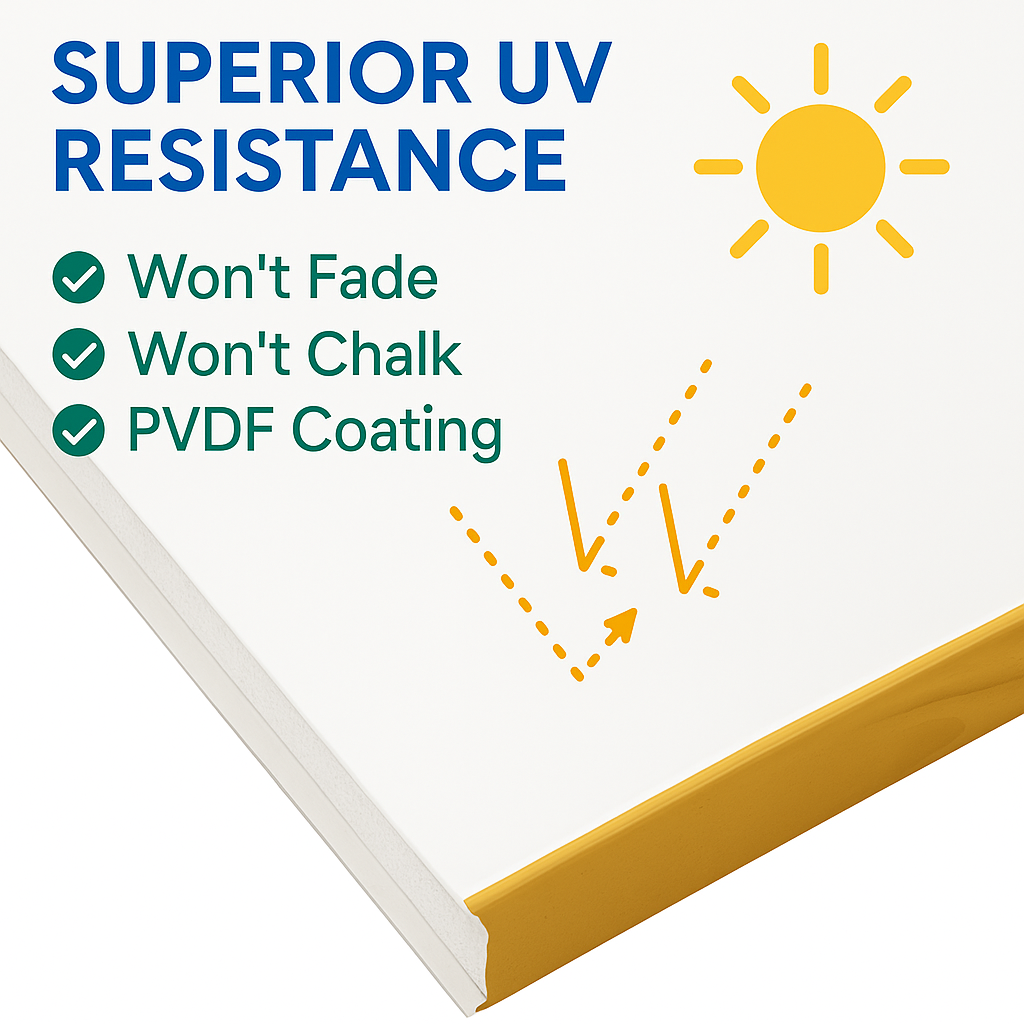

Why We Use PVDF Coating on the Surface of Panels — The Science Behind Architectural-Grade Durability

This is exactly why Bighands insulated panels are finished with premium PVDF (polyvinylidene fluoride) fluoropolymer coating — the same class of coating used on high-end architectural façades and landmark commercial projects worldwide.

PVDF is not just a nicer finish — it is a high-spec protective system that elevates the lifespan, appearance and durability of any metal-faced insulated panel.

Below is a clear explanation of why PVDF performs so well, how it works scientifically, and why it is the ideal coating for both EPS and PIR panel systems.

🌟 What Exactly Is PVDF Coating?

PVDF is a high-purity fluoropolymer coating, often branded under names such as Kynar 500® or Hylar 5000®, known for exceptional resistance to UV, chemicals and weathering.

It belongs to the highest performance coating category used in construction and meets the AAMA 2605 standard — the top benchmark for exterior architectural coatings.

In practice, this means:

- PVDF maintains colour, gloss and film integrity for decades, even under extreme conditions.

🔬 The Science Behind PVDF's Superior Performance

PVDF’s exceptional durability comes from its molecular structure. Here’s how it works:

1. Strong C–F Bond Energy (Core Advantage of Fluoropolymers)

The carbon–fluorine (C–F) bond has one of the highest bond energies in organic chemistry, giving PVDF:

- extraordinary resistance to UV radiation

- chemical inertness

- thermal stability

- resistance to oxidation and hydrolysis

Result: The coating does not break down, chalk or fade easily — even after years of exposure.

2. Semi-Crystalline Structure Improves Film Integrity

PVDF has a high degree of crystallinity, which provides:

- hardness

- abrasion resistance

- stable molecular alignment

- long-term mechanical strength

Result: The coating resists cracking, peeling, and micro-fracturing, even when the metal substrate expands or flexes.

3. Low Surface Energy for Natural Self-Cleaning

PVDF naturally repels water and contaminants, creating:

- hydrophobic surface behaviour

- reduced dirt retention

- rainwater-assisted cleaning

- long-term gloss retention

Result: The panel stays clean and visually appealing with minimal maintenance.

4. Industry-Leading Colour & Gloss Retention

PVDF coatings maintain their appearance with extremely low ΔE colour change over time. A ΔE value below 5 after long-term UV exposure is considered outstanding — and PVDF often performs at or below this level.

Result: Colours remain rich and stable for 10–20+ years, even in harsh Australian sunlight.

5. High Temperature & Chemical Resistance

PVDF coatings resist:

- acids

- alkalis

- solvents

- salt spray

- industrial pollutants

- temperatures up to ~138°C (280°F)

Result: Ideal for coastal, industrial and high-UV environments.

🌤 Why PVDF Is the Ideal Coating for Panel Surfaces

Both EPS (Expanded Polystyrene) and PIR (Polyisocyanurate) insulated panels rely on their metal exterior for long-term durability. When combined with PVDF coating, both systems achieve architectural-grade performance.

✔ PVDF + EPS Panels

EPS panels excel at:

- thermal insulation

- lightweight installation

- moisture resistance

Adding PVDF enhances EPS panels with:

- superior UV protection

- long-lasting colour

- increased corrosion resistance

- self-cleaning exterior

- improved weather durability

Ideal for: pergolas, external wall cladding, patio enclosures, and residential outdoor structures.

✔ PVDF + PIR Panels

PIR panels provide:

- higher fire performance

- better thermal efficiency

- enhanced structural stability

PVDF further strengthens PIR panels by:

- protecting the steel surface during temperature fluctuations

- preventing coating breakdown in harsh UV

- improving corrosion & chemical resistance

- maintaining façade aesthetics for commercial applications

Ideal for: commercial façades, cold storage, industrial buildings and high-performance exterior applications.

🌟 The Result: A Premium Insulated Panel System for Australian Conditions

- Better long-term durability

- Superior weather and UV resistance

- Colour and gloss retention for decades

- Reduced maintenance cost

- Higher resistance to corrosion and pollutants

- A cleaner, more attractive appearance over time

This is why PVDF is considered the gold standard for high-quality metal cladding — and why we use it on our panels.

Why Bighands Chooses PVDF

Our goal is simple: to offer panels that look better, last longer, and perform reliably for years.

Many low-cost panels use polyester or SMP coatings that fade, chalk or deteriorate quickly. PVDF ensures:

- longer lifespan

- architectural-grade performance

- stability under extreme sunlight

- superior outdoor durability

- better value across the entire service life

When you choose Bighands panels with PVDF coating, you are choosing a premium system designed for real Australian environments.