Recent Articles

Polycarbonate in Home Design

The contemporary look of the material has made it popular in the last few years in award winning architectural projects, especially in Europe.

Here, we share some of our favourite projects which have used polycarbonate in a stylish and clever way.

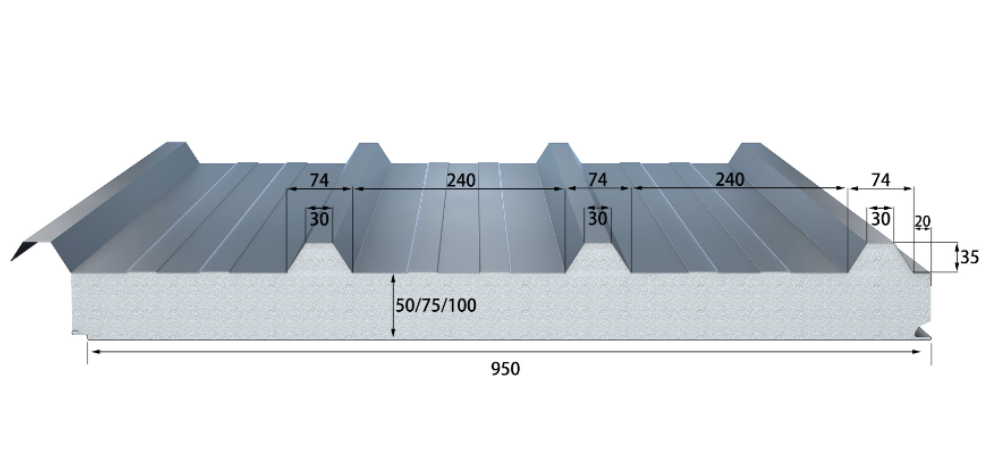

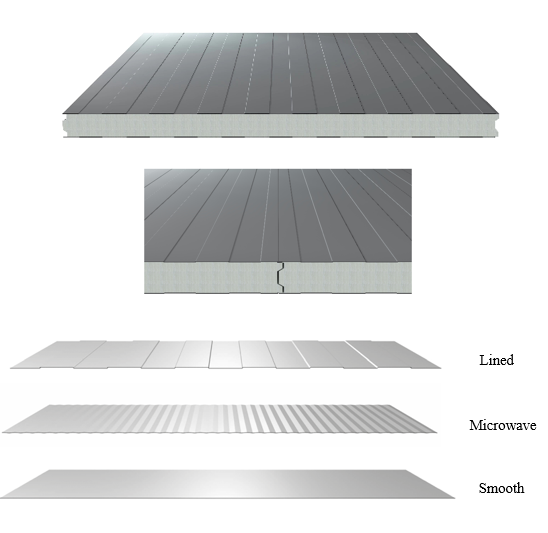

EPS Panel vs. PIR Panel | How to Choose the Right Building Material?

🔹 EPS Panel (Expanded Polystyrene Panel) – 50mm / 75mm Thickness

EPS Panels consist of a high-density expanded polystyrene (EPS) core sandwiched between metal or other composite facings. They offer excellent thermal insulation, cost efficiency, and easy installation, making them a practical and economical building material.

✨ Key Advantages:

✅ Cost-Effective – Lower cost, ideal for large-scale use ✅ Good Thermal Insulation – Low thermal conductivity, reducing energy loss and improving efficiency ✅ Lightweight & Easy Installation – Lightweight structure, easy to transport and install, reducing labor costs ✅ Impact Resistance – Strong load-bearing capacity, maximum span up to 5m ✅ Sound Insulation – Helps reduce noise, improving indoor comfort ✅ Certified Quality – NATA-certified, ensuring safety and reliability🔸 Applications:

General building enclosures, cold storage, temporary buildings, interior partitions, canopies, and more

🔹 PIR Panel (Polyisocyanurate Panel) – 100mm Thickness

PIR Panels use a closed-cell polyisocyanurate (PIR) foam core, offering superior thermal insulation compared to EPS. They also provide higher fire resistance and durability, making them an excellent choice for high-end and specialized applications.

✨ Key Advantages:

✅ Superior Thermal Insulation – Ultra-low thermal conductivity of 0.022W/(m·K), outperforming EPS ✅ Excellent Fire Resistance – B1-rated or higher, non-combustible and no dripping under high temperatures ✅ High Structural Stability – Strong resistance to temperature variations, prevents deformation and cracking ✅ Chemical & Corrosion Resistance – Ideal for humid, high-temperature, and corrosive environments, extending building lifespan ✅ Water & Moisture Resistance – Low water absorption, preventing mold growth, suitable for long-term use ✅ High Strength – Superior load-bearing capacity, suitable for structurally demanding applications ✅ Certified Safety – FM-approved, meeting strict fire and safety regulations🔸 Applications:

High-end buildings, industrial facilities, cold chain logistics, food processing plants, clean rooms, cold storage, medical laboratories, and more

💡 How to Choose?

✅ Budget-Conscious & Basic Insulation Needs → Choose EPS Panel, cost-effective 💰 ✅ Higher Fire Resistance & Superior Insulation Performance → Choose PIR Panel, safe & durable 🔥 By considering your budget, environmental conditions, and building requirements, you can choose the most suitable material to ensure safety, durability, and energy efficiency for your project! 🏗️ ✅

Decking Accessories Guide – Enhance Your Decking Installation!

🔹 Plastic Bracket – Seamless Decking Connection

✅ Maintains a 6mm gap between two decking boards, allowing for proper ventilation and expansion. ✅ Recommended usage: 12 pieces per decking board length. ✅ Function: Designed to connect decking boards, ensuring a smooth and uniform alignment.

🔹 Metal Bracket – Stability & Positioning

✅ Maintains a 6mm gap between decking boards. ✅ Placement: Used at the beginning and end of a decking board length. ✅ Function: Helps fix the position of each board, preventing movement over time. ✅ Combination: Always used with Plastic Brackets – Metal Brackets provide stability, while Plastic Brackets connect the boards.

🔹 Decking Wings – Independent Spacing Solution

✅ Maintains a 4mm gap between decking boards for a refined appearance. ✅ Standalone Usage: Unlike brackets, Decking Wings do not require additional connectors and can be used independently.

🔹 Decking Edge – Achieve a Clean, Finished Look

✅ Function: Helps create a perfect strip line, ensuring a neat and professional-looking decking border. ✅ Benefit: Enhances the overall appearance by giving the edges a sharp and defined look.

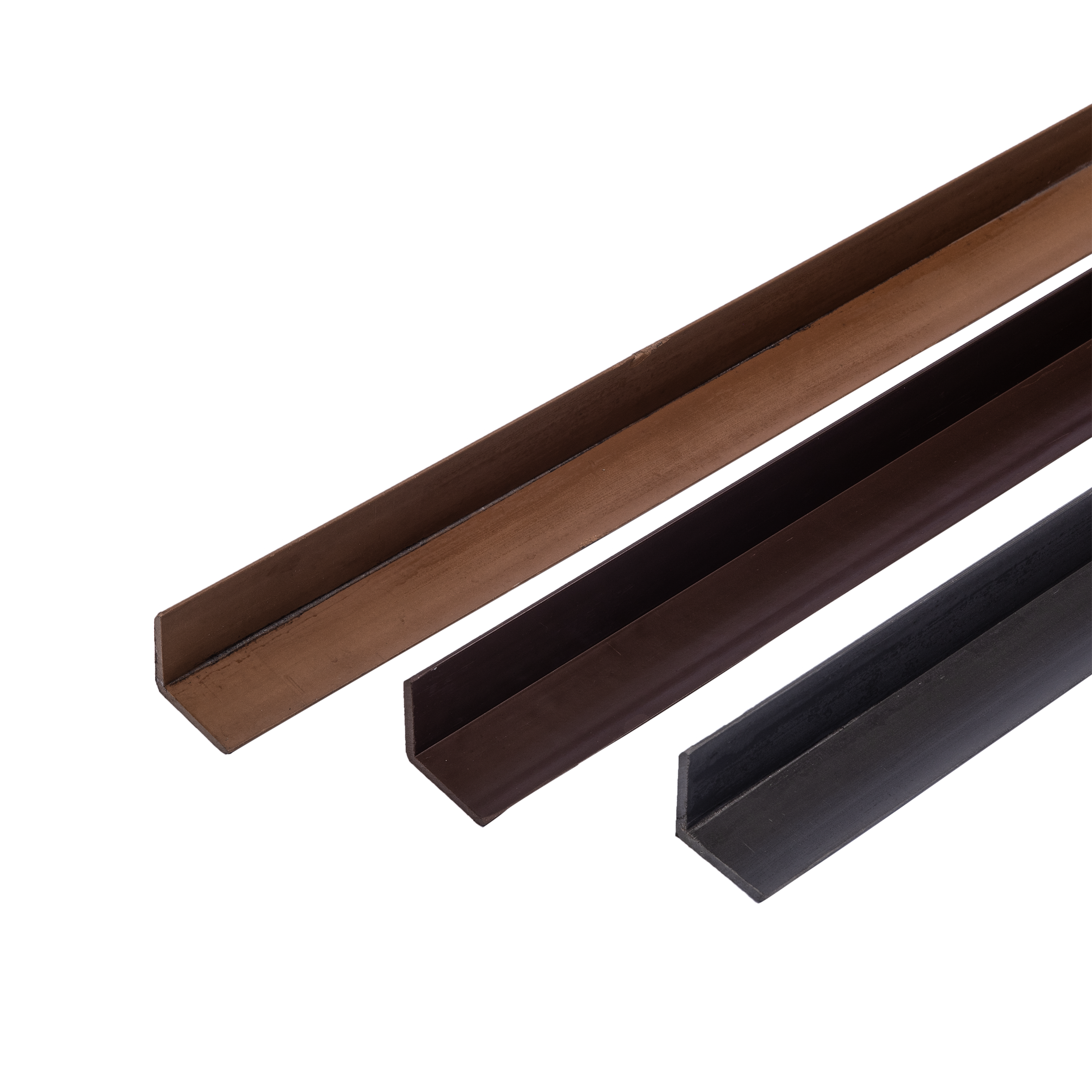

🔹 Decking Corner – A Stylish Way to Conceal Edges

✅ Purpose: Provides an alternative way to hide exposed edges, creating a sleek and seamless transition. ✅ Design: Features an angled structure that makes both sides of the decking look visually balanced. By using the right accessories from Bighands Building Supply, a trusted decking supplier, you can enhance the durability, alignment, and aesthetic appeal of your decking. These components ensure a professional finish, making your decking installation more efficient and visually stunning! 🌿✨

By using the right accessories from Bighands Building Supply, a trusted decking supplier, you can enhance the durability, alignment, and aesthetic appeal of your decking. These components ensure a professional finish, making your decking installation more efficient and visually stunning! 🌿✨

Aluminium Carport🚗 – Stylish, Durable, and Easy to Install!

Key Features:

✅ High-Strength Aluminium Alloy Frame: Low maintenance and corrosion-resistant. 🎨 Powder Coated Finish: Adds durability and a sleek, modern look. ☀️ Roofing Options: Polycarbonate Roofing: Blocks 98% of UV rays and offers high impact resistance. Cooldek Roofing: Provides superior insulation, reducing heat buildup and keeping your vehicle cooler.

Cooldek Roofing: Provides superior insulation, reducing heat buildup and keeping your vehicle cooler.

🌬️ Weatherproof Design: Withstands strong winds up to 42m/s.

🔧 Easy Assembly: All necessary parts included for quick installation.

🌈 Multiple Colour Options: Choose from a range of colours to match your style.

🌬️ Weatherproof Design: Withstands strong winds up to 42m/s.

🔧 Easy Assembly: All necessary parts included for quick installation.

🌈 Multiple Colour Options: Choose from a range of colours to match your style.

Available Sizes:

📏 Single Carport (for one vehicle): Dimensions: 5.5m (L) x 3.1m (W) x 3.0m (H) Coverage: 17.05m² 📐 Double Carport (for two vehicles):

Dimensions: 5.5m (L) x 6.2m (W) x 3.0m (H)

Coverage: 34.10m²

📐 Double Carport (for two vehicles):

Dimensions: 5.5m (L) x 6.2m (W) x 3.0m (H)

Coverage: 34.10m²

Why Choose Our Carport?

🛡️ Protection: Safeguard your vehicle from sun, rain, and wind. 💪 Durability: Built to last with premium materials. 🏡 Versatility: Suitable for homes, businesses, and more.

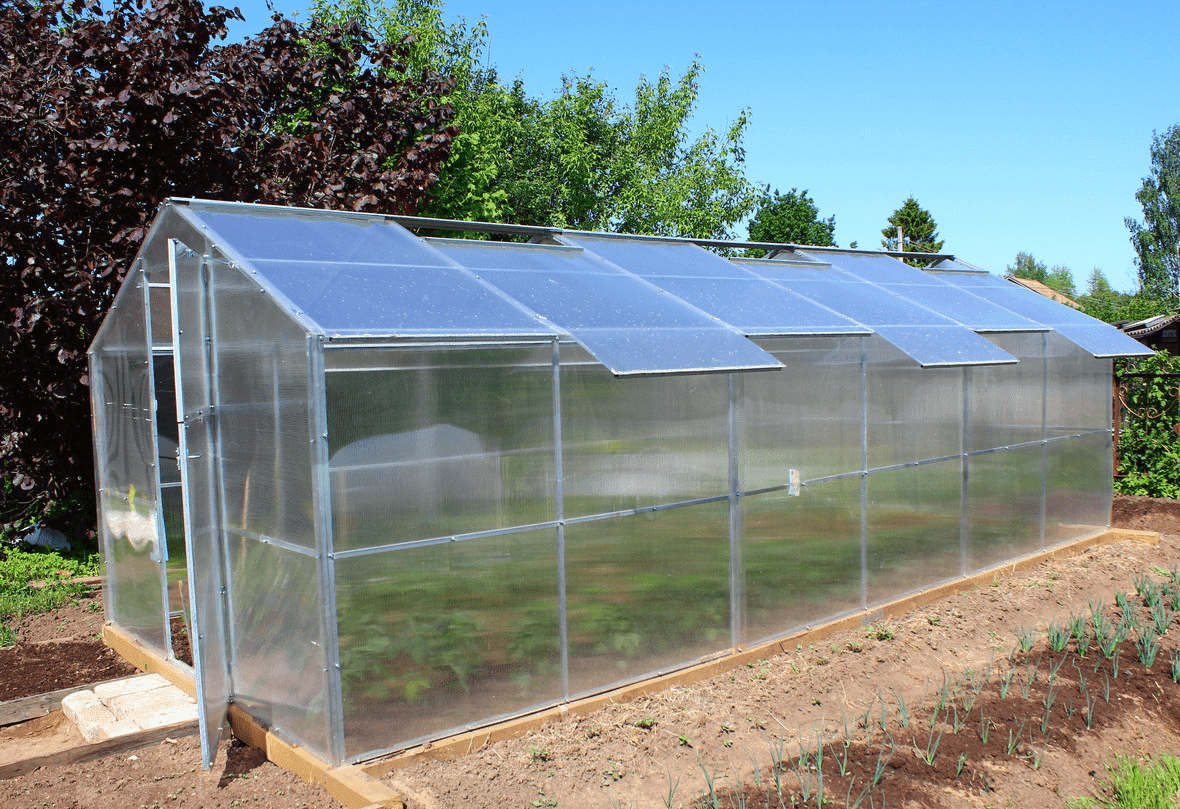

The Differences Between Twin Wall, Solid PC, and Single-Layer PC Sheets

1️⃣ Twin Wall Polycarbonate Sheets

Structure: Composed of two parallel layers supported by internal ribs, creating a hollow, multi-channel design. Key Features: ✅ Lightweight & Easy to Install – The hollow structure makes it lighter and easier to handle than solid sheets. ✅ Excellent Thermal Insulation – Reduces heat loss and helps maintain a stable indoor temperature, making it ideal for greenhouses, skylights, and roofing. ✅ Durable & Weather-Resistant – Offers high impact resistance and often comes with a UV protection layer, ensuring long-lasting performance even in harsh weather conditions. ✅ Cost-Effective – More affordable than solid sheets while still providing good strength and insulation. Applications: 🌿 Greenhouses | ☀️ Sunrooms | 🏡 Roofing | 🏢 Partitions

2️⃣ Solid Polycarbonate Sheets

Structure: A single, thick layer of solid polycarbonate without any hollow structure. Key Features: ✅ High Impact Strength – Extremely durable and widely used in security and protective applications. ✅ Exceptional Transparency – Offers optical clarity close to glass but is lighter and more impact-resistant. ✅ Weather-Resistant – Can be coated with a UV protection layer to prevent yellowing and degradation, making it suitable for long-term outdoor use. ✅ Heavier Weight – Requires a more robust support structure, making it more suited for fixed installations. Applications: 🏢 Security windows | 🛡️ Bullet-resistant barriers | 🏭 Machine guards | 🌞 Transparent roofing

3️⃣ Single-Layer Polycarbonate Sheets

Structure: A thin, single-layer polycarbonate sheet, making it the lightest option among the three. Key Features: ✅ Lightweight & Easy to Cut – Can be easily processed and installed, making it ideal for projects requiring quick customization. ✅ Flexible – Can be bent or rolled, allowing for creative and curved designs. ✅ Good Light Transmission – Offers high transparency, though it has lower strength and insulation compared to Twin Wall and Solid PC sheets. ✅ Cost-Effective – The most budget-friendly option, suitable for applications where high strength is not a priority. Applications: 📌 Signage | 🛡️ Protective covers | 🏡 Lightweight roofing | 🎨 DIY projects

Choosing the Right PC Sheet

✅ Twin Wall – Ideal for applications requiring thermal insulation, durability, and cost efficiency, such as greenhouses, sunrooms, and roofing. ✅ Solid PC – Best suited for high-strength, high-transparency, and security-focused applications, such as safety windows, bullet-resistant panels, and machine guards. ✅ Single-Layer PC – A practical choice for lightweight, flexible, and economical solutions, including signage, protective covers, and DIY projects. Each type of polycarbonate sheet offers unique benefits, and selecting the right one depends on the specific requirements of the project.

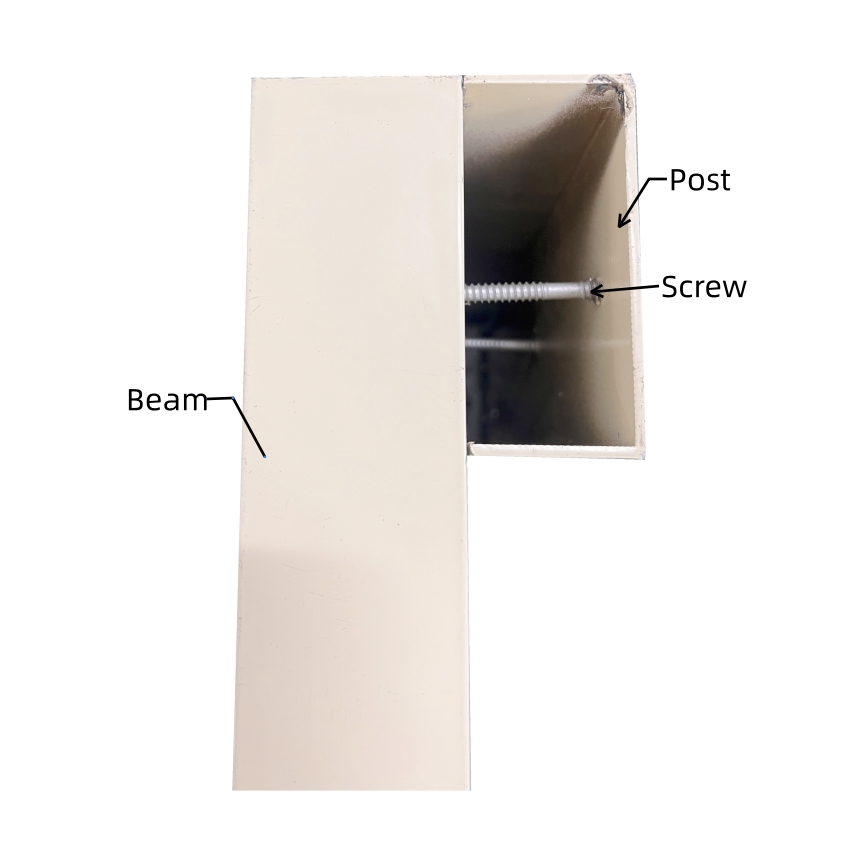

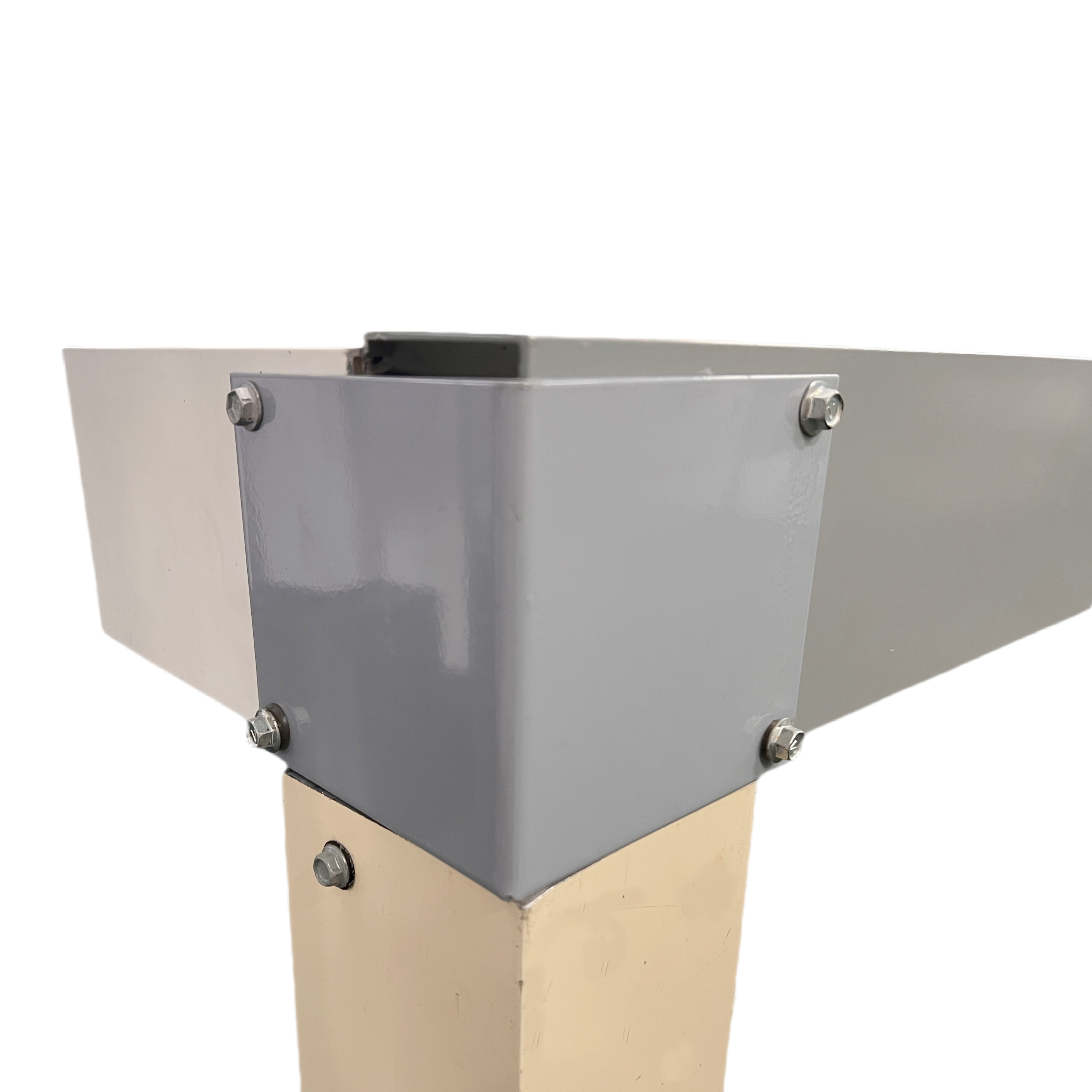

Effortless Beam-to-Post Connections with Versatile Brackets!

Recommended Bighands Brackets

🔹 Beam Bracket

Designed for direct beam-to-post/beam-to-beam connections with a simple installation process.

Installation: Secure the bracket to the post or beam, insert the other beam, and fasten it with screws.

Ideal for standard framework structures.

🔹 Angle Bracket

Perfect for slanted or triangular roofs, allowing for precise 45° angled connections that ensure both structural integrity and visual appeal.

🔹 Gable Bracket

Specifically designed for triangular roofs, seamlessly connecting slanted beams on both sides.

No need for additional cutting—this single bracket covers all joints, making the process more efficient and visually refined.

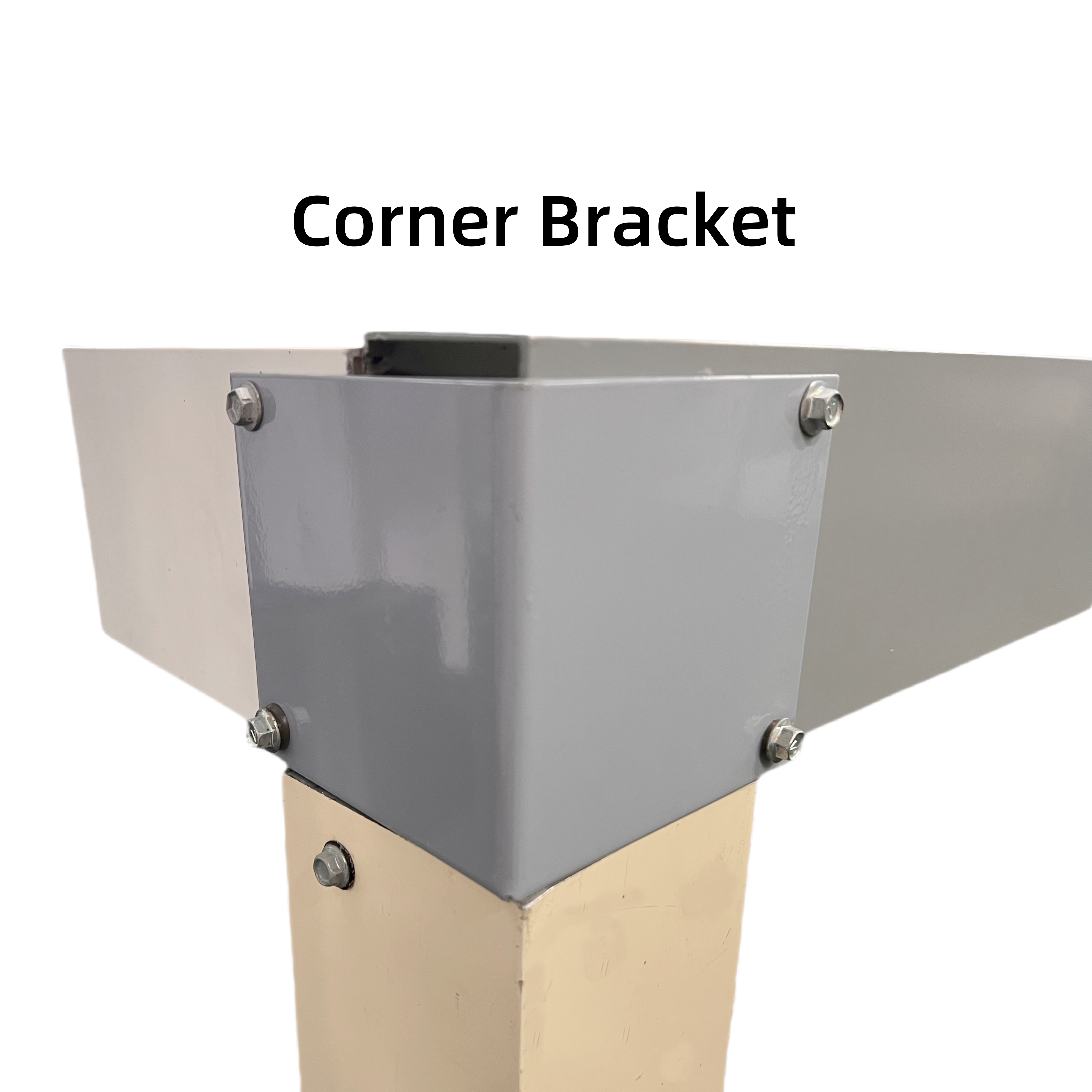

🔹 Corner Bracket

Suitable for 90° right-angle connections, particularly designed for aluminum structures.

Effectively conceals joint imperfections, resulting in a neater and more professional framework.

Why Choose Bighands Brackets?

✅ Easy Installation – No complex procedures required, allowing for quick and effortless beam-to-post connections.

✅ Aesthetic & Functional – Neatly conceals joints to enhance overall appearance.

✅ Versatile Options – Designed to accommodate different angles and structures, ensuring adaptability to various framework designs.

Installation Tips

📌 Plan ahead based on your pergola design to determine the optimal bracket placements.

📌 Ensure screws are tightly secured during installation to maintain structural stability and safety.

With Bighands brackets, building your pergola becomes more efficient and durable. Achieve your ideal structure with ease—get yours today and start your DIY project!

🔹 Gable Bracket

Specifically designed for triangular roofs, seamlessly connecting slanted beams on both sides.

No need for additional cutting—this single bracket covers all joints, making the process more efficient and visually refined.

🔹 Corner Bracket

Suitable for 90° right-angle connections, particularly designed for aluminum structures.

Effectively conceals joint imperfections, resulting in a neater and more professional framework.

Why Choose Bighands Brackets?

✅ Easy Installation – No complex procedures required, allowing for quick and effortless beam-to-post connections.

✅ Aesthetic & Functional – Neatly conceals joints to enhance overall appearance.

✅ Versatile Options – Designed to accommodate different angles and structures, ensuring adaptability to various framework designs.

Installation Tips

📌 Plan ahead based on your pergola design to determine the optimal bracket placements.

📌 Ensure screws are tightly secured during installation to maintain structural stability and safety.

With Bighands brackets, building your pergola becomes more efficient and durable. Achieve your ideal structure with ease—get yours today and start your DIY project!

Why Choose Bighands Brackets?

✅ Easy Installation – No complex procedures required, allowing for quick and effortless beam-to-post connections. ✅ Aesthetic & Functional – Neatly conceals joints to enhance overall appearance. ✅ Versatile Options – Designed to accommodate different angles and structures, ensuring adaptability to various framework designs.Installation Tips

📌 Plan ahead based on your pergola design to determine the optimal bracket placements. 📌 Ensure screws are tightly secured during installation to maintain structural stability and safety. With Bighands brackets, building your pergola becomes more efficient and durable. Achieve your ideal structure with ease—get yours today and start your DIY project!

🌟 Multiple Methods for Connecting Aluminium Beams and Posts🌟

Method 1: Notching Technique

1️⃣ Mark the Position

On the post, accurately mark the area corresponding to the width and height of the beam. Use a measuring tape and square to ensure precision. 📏

2️⃣ Cut the Notch

Using a saw, carefully cut out the marked section on the post. Ensure the depth and width of the notch match the beam dimensions for a snug fit. ✂️

3️⃣ Fit the Beam

Insert the beam into the notch, ensuring a seamless and flush connection. This method provides excellent load-bearing support. 🔗

4️⃣ Secure the Connection

Fasten the beam to the post using structural screws or bolts. Ensure the fasteners are appropriately sized and spaced for maximum stability. 🔩

1️⃣ Mark the Position

On the post, accurately mark the area corresponding to the width and height of the beam. Use a measuring tape and square to ensure precision. 📏

2️⃣ Cut the Notch

Using a saw, carefully cut out the marked section on the post. Ensure the depth and width of the notch match the beam dimensions for a snug fit. ✂️

3️⃣ Fit the Beam

Insert the beam into the notch, ensuring a seamless and flush connection. This method provides excellent load-bearing support. 🔗

4️⃣ Secure the Connection

Fasten the beam to the post using structural screws or bolts. Ensure the fasteners are appropriately sized and spaced for maximum stability. 🔩

Method 2: Connector-Based Technique

1️⃣ Install a U-Shaped Connector

Position a U-shaped connector inside the post and secure it with heavy-duty screws. This creates a stable platform for the beam.

2️⃣ Attach an L-Shaped Corner Connector

Fix an L-shaped corner connector onto the U-shaped platform, ensuring the angle is precisely 90 degrees. Use a level to verify accuracy. 📐

3️⃣ Insert and Secure the Beam

Slide the beam into the connector from both sides. Secure the beam by driving screws through the sides of the connector into the beam. 🔗

1️⃣ Install a U-Shaped Connector

Position a U-shaped connector inside the post and secure it with heavy-duty screws. This creates a stable platform for the beam.

2️⃣ Attach an L-Shaped Corner Connector

Fix an L-shaped corner connector onto the U-shaped platform, ensuring the angle is precisely 90 degrees. Use a level to verify accuracy. 📐

3️⃣ Insert and Secure the Beam

Slide the beam into the connector from both sides. Secure the beam by driving screws through the sides of the connector into the beam. 🔗

Conclusion

Both methods offer reliable solutions for connecting beams to posts, with the notching technique providing a more integrated look and the connector-based method offering flexibility and ease of assembly. The choice depends on your project requirements, tools, and desired aesthetic. Which method do you find more suitable for your construction needs? Share your thoughts below!

Why Choose Aluminium Structural Products for Your Building Structure?

Comparison Between Aluminium Alloy and Iron

1. Density and Weight- Aluminium Alloy: Density is about 2.7 g/cm³, making it lightweight and ideal for weight-sensitive applications like aerospace and automotive manufacturing.

- Iron: Density is about 7.87 g/cm³, making it heavier and more suitable for construction and heavy machinery.

- Aluminium Alloy: Moderate strength, but can be enhanced through alloying and heat treatment. Some high-strength aluminium alloys are comparable to steel.

- Iron: Pure iron has low strength, but carbon steel and alloy steel are much stronger, making them ideal for high-load applications.

- Aluminium Alloy: Forms a protective oxide layer, offering excellent corrosion resistance, especially in humid or corrosive environments.

- Iron: Prone to rust and requires protective measures like galvanizing or painting to improve corrosion resistance.

- Aluminium Alloy: Excellent thermal and electrical conductivity, often used in heat sinks and electrical components.

- Iron: Poorer thermal and electrical conductivity compared to aluminium.

- Aluminium Alloy: Easy to process, suitable for casting, extrusion, and machining, with lower processing costs.

- Iron: Good workability, but harder grades are more difficult to process, increasing costs.

- Aluminium Alloy: Higher material cost, but lightweight properties reduce transportation and installation expenses.

- Iron: Lower cost and abundant resources, making it suitable for large-scale applications.

- Aluminium Alloy: Widely used in aerospace, automotive, electronics, and packaging industries.

- Iron: Mainly used in construction, bridges, machinery, and heavy equipment.

- Aluminium Alloy: Can be anodized or coated for a modern, sleek appearance.

- Iron: Often used for retro or industrial-style designs.

Summary

Aluminium alloy, with its lightweight, corrosion resistance, and excellent thermal and electrical conductivity, has become an indispensable material in modern industry, particularly suited for applications requiring lightweight and corrosion-resistant properties. On the other hand, iron, with its high strength and low cost, plays a vital role in construction and heavy machinery where strength and cost-effectiveness are critical. Both materials have their unique advantages, and the choice should be based on specific needs and application scenarios. Whether you prefer the modern and lightweight appeal of aluminium alloy or the rustic and robust charm of iron, both can contribute to your construction projects, showcasing distinct styles and characteristics.

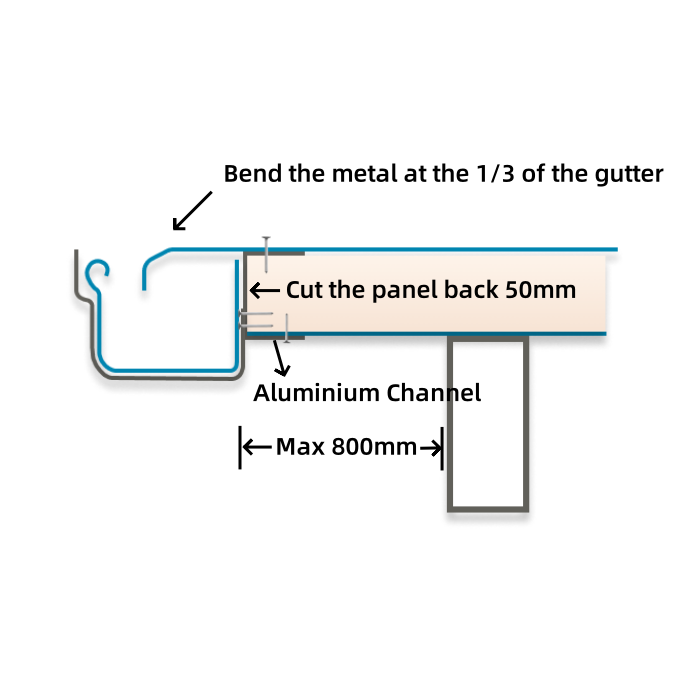

Guide to Installing a Gutter System for EPS Pergola

Guide to Installing an Overhang Gutter System

Installation Steps

1.Cut the Ceiling Side Metal and Foam Cut back the ceiling side metal and foam on the panel by about 50mm. 2.Fix the U-Channel Insert the U-channel between the roof side metal and the foam. Secure it firmly with screws from both the top and bottom. 3.Install the Gutter Hooks Nail the gutter hooks onto the U-channel at 1-meter intervals. 4.Place the Gutter Carefully place the gutter onto the hooks. 5.Bend the Steel Sheet Bend the roof side metal sheet downward at about 1/3 of the gutter’s width to create a slope, allowing water to flow smoothly into the gutter.Why Choose the Overhang Style?

✅ The Bighands Building EPS Panels are capable of overlapping up to approximately 800mm, ensuring a secure and stable connection. ✅ Enhanced Protection: The overhang design provides additional coverage, shielding your pergola and outdoor space from rain, sun, and debris. ✅ Improved Shade: Extends the shaded area, creating a more comfortable outdoor environment for relaxation or entertainment. ✅ Architectural Appeal: Adds a visually striking element to your pergola, enhancing its overall design and aesthetic value. ✅ Versatile Functionality: Perfect for integrating with lighting and fans, offering both practicality and beauty. ✅ Durable Performance: The overhang structure is designed to withstand weather elements, ensuring long-lasting durability and stability.Guide to Installing a No-Overhang Gutter System

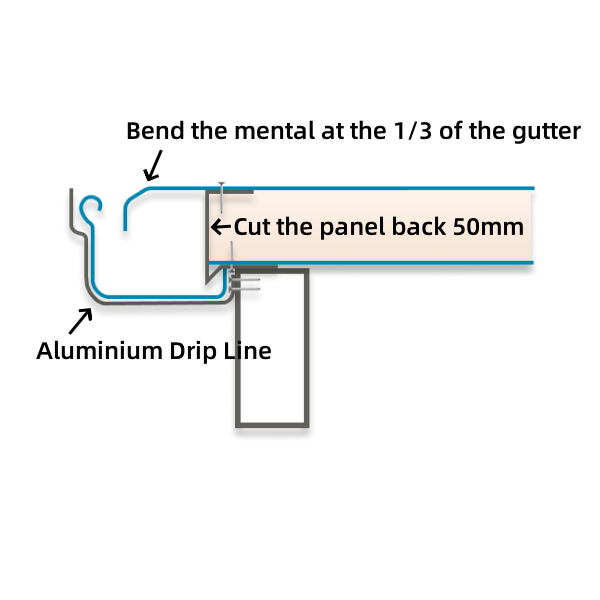

Installation Steps

1.Choose the Right Accessories Use Bighands Drip Line, specially designed for panel structures, to ensure a perfect fit and smooth drainage. 2.Cut the Ceiling Side Metal and Foam Trim approximately 50mm from the ceiling side metal and foam backing to create space for the drip line installation. 3.Install the Drip Line Insert the drip line into the roof side metal, making sure it fully wraps around the foam for waterproofing and protection. 4.Secure the Gutter Brackets Nail the gutter hooks onto the U-channel at 1-meter intervals. 5.Place the Gutter Position the gutter into the brackets and adjust it to align seamlessly with the drip line. 6.Adjust the Roof Sheet Angle Bend the roof sheet downward at a one-third point of the gutter to create a natural slope, allowing water to flow smoothly into the gutter and preventing pooling.Why Choose the No-Overhang Style?

✅ Space-Saving: Ideal for pergolas without overhangs, maximizing the use of column edge space. ✅ Efficient Drainage: The combination of drip line and gutter ensures rainwater is quickly diverted, protecting the pergola structure. ✅ Aesthetic and Functional: The installation is neat and visually appealing, complementing the overall design of the pergola.

Spend Less, Get More! 5 Key Advantages of PC Over PVC

PC panels outperform PVC in durability, transparency, heat resistance, and eco-friendliness, making them the superior choice for long-term use in construction and beyond.

Didn't Read version

5 Core Benefits of PC Panels:

1️⃣ Impact-Resistant & Hail-Proof – Stays intact even in extreme weather conditions.

2️⃣ Eco-Friendly & Recyclable – Reduces environmental impact and supports sustainability.

3️⃣ Naturally Transparent & Crystal Clear – Enhances lighting and elevates space aesthetics.

4️⃣ High-Temperature Resistant – Maintains stability without deformation in extreme heat.

5️⃣ Lightweight & Easy to Install – Saves construction time and labour costs.

PC Building Materials: Our Three Promises:

✅ No Replacement Needed for 10 Years – Reduces maintenance costs by 70%, making it a cost-effective long-term investment.

✅ Quiet Indoors on Rainy Days – Minimizes noise disturbances, improving resident satisfaction by 50%.

✅ Enhanced Building Aesthetics – Upgrades architectural appeal, boosting customer satisfaction by 100%.

In-Depth Analysis

PC (Polycarbonate) and PVC (Polyvinyl Chloride) are both commonly used plastics in construction, electronics, automotive, and packaging. However, PC panels offer superior performance in key areas.

| Feature | PC (Polycarbonate) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Transparency | High (89% light transmission) | Low to medium (requires additives to improve transparency) |

| Impact Resistance | Extremely strong (250x that of glass) | Weak (easily cracks) |

| Temperature Resistance | -100°C to 130°C | -15°C to 60°C |

| Environmental Friendliness | 100% recyclable, halogen-free flame retardants | Contains chlorine, may release harmful substances when discarded |

| Lifespan | 10-15 years | 5-8 years (prone to aging in outdoor use) |

| Cost | Relatively high | Relatively low |

Here’s why PC is the better choice:

1️ Impact-Resistant & Hail-Proof – The “Safety Guardian” in Extreme Weather

PC panels have 250 times the impact strength of regular glass and 30 times that of acrylic, making them highly resistant to hail and strong winds. This is why PC materials are widely used in automotive lighting systems, where they account for over 50% of car light plastics. Their durability makes them ideal for outdoor skylights, greenhouses, and roofing, ensuring structural integrity even in harsh weather conditions.

2️ Eco-Friendly & Recyclable – The Future of Green Building

PC panels are 100% recyclable and free from halogen-based flame retardants, meaning they do not release toxic gases when burned. In contrast, PVC panels contain chlorine, which can release harmful dioxins when disposed of, making them far less environmentally friendly.

3️ Naturally Transparent & Crystal Clear – Superior Lighting Performance

PC panels boast up to 89% light transmission, with a light degradation rate of just 6% over 10 years—significantly better than PVC's 15-20% degradation rate. Their UV-resistant coating ensures long-term clarity without yellowing or fogging. This is why high-end smart home devices often use modified PC for infrared lenses and speaker casings, offering both functionality and aesthetics.

4️ High-Temperature Resistant – Built for Extreme Environments

PC panels can withstand temperatures ranging from -100°C to 130°C without warping, softening, or losing stability. This makes them perfect for high-temperature industrial settings, such as automotive engine components and outdoor display enclosures. Meanwhile, PVC panels soften and deform above 60°C, limiting their application in high-heat environments.

5️ Lightweight & Easy to Install – Revolutionizing Construction Efficiency

With a density of just 1.2g/cm³, PC panels are 50% lighter than glass and even lighter than PVC panels. In construction, this reduces steel framework costs and improves installation efficiency by over 30%. Additionally, their low thermal expansion minimizes the need for complicated gap allowances, cutting down on labour and project timelines.

Why Upgrade to PC Panels?

✅ No Replacement Needed for 10 Years – Reduces Maintenance Costs by 70%

PC panels have a lifespan of 10-15 years, with minimal degradation. For example, PC noise barriers on highways effectively block up to 40dB of sound while maintaining durability—whereas PVC panels degrade too quickly for long-term outdoor use.

✅ Quiet Indoors on Rainy Days – Reduces Noise Disturbances by 50%

PC panels with multi-layer hollow structures effectively absorb rain impact noise. In contrast, PVC panels resonate loudly during storms, disrupting indoor comfort.

✅ Enhanced Building Aesthetics – Increases Customer Satisfaction by 100%

PC panels can be customized with glass-like or metallic finishes, making them perfect for high-end architectural designs. In smartphone manufacturing, ultra-tough modified PC is used for high-pressure molded glass-like back covers, balancing durability and aesthetics.

Upgrade from PVC to PC: A Game-Changer for Quality and Value

PC panels are rapidly replacing traditional materials in construction, automotive, and electronics due to their superior durability, environmental benefits, and performance. Choosing PC is not just a cost-saving move—it’s an investment in longevity, safety, and sustainability.

Make the switch today! Enjoy the benefits of long-lasting durability, energy efficiency, and stunning aesthetics with PC panels!

Holiday Closure Announcement

Holiday Closure Dates:

- December 13, 2024: Last day for pre-Christmas orders of Colourbond Roof, Gutter, and Flashing. - December 21, 2024: January 12, 2025 (inclusive): Shop closed. - January 13, 2025: Shop reopens; deliveries and order pick-ups resume. Our sales and customer service teams are available to assist with any questions or support related to product orders before the holidays. Thank you for choosing Bighands Building Supply this year. We wish you a Merry Christmas and a joyous holiday season! Best regards, Bighands Building Supply

Why Polycarbonate is Perfect for Your Greenhouse

Polycarbonate in Home Design

The contemporary look of the material has made it popular in the last few years in award winning architectural projects, especially in Europe.

Here, we share some of our favourite projects which have used polycarbonate in a stylish and clever way.